Address:

No.233-3 Yangchenghu Road, Xixiashu Industrial Park, Xinbei District, Changzhou City, Jiangsu Province

Processing large-diameter threads and deep, complex geometries presents unique challenges that set thread milling cutters apart from traditional threading tools. Unlike taps or single-point threading, thread milling uses a rotating cutter that removes material with precise, controlled passes, making it highly effective for difficult thread profiles and oversized dimensions. Our manufacturing expertise ensures that the thread milling tools we supply meet stringent demands for accuracy and durability, especially when handling complex parts.

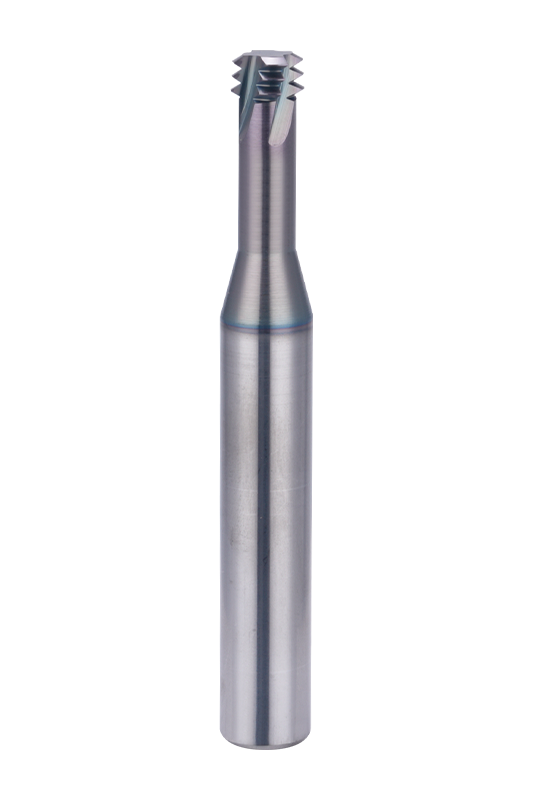

Large-diameter threads require special attention due to increased cutting forces and potential for tool deflection. A thread milling cutter designed for such applications must feature robust construction, optimized flute geometry, and often multi-tooth configurations to distribute the load evenly. These design considerations help maintain thread accuracy and surface finish while minimizing vibration, which is critical in machining large threads on both internal and external surfaces.

Deep threads add another layer of complexity by limiting chip evacuation and coolant flow within the cutting zone. High-performance thread milling cutters with advanced flute designs enable efficient chip removal and coolant delivery, reducing heat buildup and tool wear. This leads to longer tool life and consistent thread quality. When dealing with intricate geometries, especially on complex workpieces, the adaptability of thread milling cutters becomes a significant advantage, as they can machine multiple thread sizes and pitches with the same tool by adjusting the programmed path.

Complex thread profiles, such as those with variable pitch or non-standard forms, are difficult to achieve with conventional threading methods. Thread milling cutters excel here because they can be programmed to follow virtually any thread path, allowing manufacturers to produce specialized threads without the need for custom taps. This flexibility also reduces tool inventory and machining setup times, which is a critical benefit for production environments handling diverse or small-batch runs.

Our thread milling cutter offerings incorporate premium materials and coatings to withstand the demands of challenging thread applications. Carbide substrates combined with advanced coatings enhance wear resistance and reduce friction, enabling stable machining of tough materials and maintaining tight tolerances even in large or complex threads. This level of performance reflects our commitment to providing tools that support high precision and efficiency.

Another important aspect is the integration of these thread milling tools with CNC machining centers capable of multi-axis movement. The combination allows machining of complex geometries in a single setup, improving overall process efficiency and eliminating the risk of misalignment between thread features. This synergy between tooling and machine technology is essential to achieving the high-quality results required by modern manufacturers.

Choosing the right thread milling cutter from a reputable manufacturer ensures not only tool quality but also access to expert technical support for optimizing machining parameters. Proper feed rates, spindle speeds, and depth of cut tailored to large or complex thread machining maximize productivity and tool life. Our experience helps customers navigate these variables, ensuring their investment in thread milling technology delivers measurable benefits.

For businesses aiming to expand their threading capabilities with precision and reliability, investing in specialized thread milling cutters designed for large-diameter and complex threads is a smart move. Our product line stands out with a balance of durability, adaptability, and performance — qualities that bring clear value to any machining operation seeking to elevate its thread production standards.