Address:

No.233-3 Yangchenghu Road, Xixiashu Industrial Park, Xinbei District, Changzhou City, Jiangsu Province

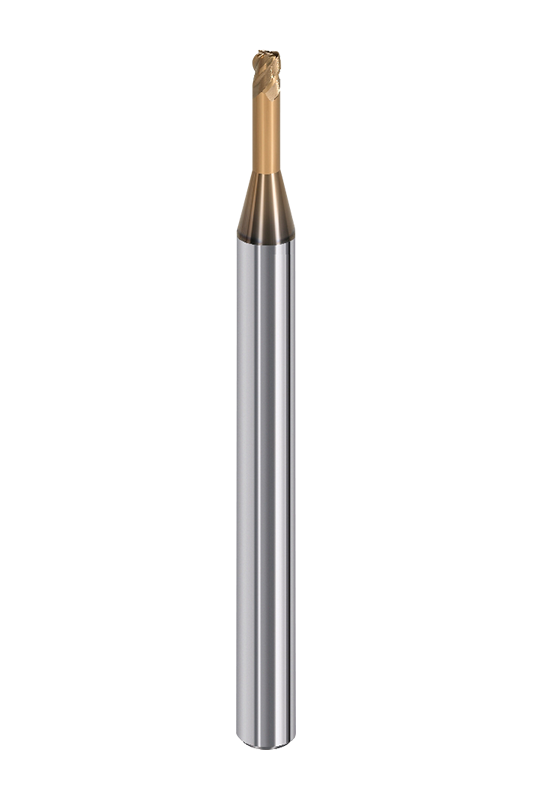

High-speed steel end mills are widely used in the manufacturing industry due to their excellent wear resistance, toughness, and versatility. When it comes to machining tough tool steels, such as P20, 718H, NAK80, and H13, the right cutting tool can make a significant difference in efficiency, tool life, and the overall quality of the finished part. In this article, we’ll explore how HSS end mills perform when machining these materials, and why they are an excellent choice for both soft and hard material processing.

1. Understanding the Materials: P20, 718H, NAK80, and H13

P20 Tool Steel: Commonly used for molds and dies, P20 is a pre-hardened tool steel with moderate hardness. It is known for its good machinability and is often used for making molds for plastics and light metal casting.

718H (Inconel 718): A high-strength nickel-chromium alloy, Inconel 718 is typically used in high-temperature environments like aerospace and turbine engines. It is known for its strength, toughness, and resistance to oxidation and corrosion.

NAK80: This is a high-quality mold steel used primarily in plastic injection molds. NAK80 offers high hardness, excellent polishability, and is often used in fine-feature mold making due to its ability to hold tight tolerances.

H13 Tool Steel: A hot-work tool steel, H13 is designed for high-temperature applications. It’s commonly used for dies and molds that operate in hot conditions, such as in the metal forming industry.

2. Performance of HSS End Mills on Different Materials

Each of these materials presents its own unique challenges when it comes to machining. The sharpness, wear resistance, and toughness of HSS end mills make them highly effective for processing a range of hard and soft materials. Here’s how they perform with each:

P20 Tool Steel: HSS end mills are an excellent choice for machining P20 due to the material’s moderate hardness. These tools provide high precision and are capable of maintaining a sharp cutting edge, resulting in smooth finishes and long tool life. The excellent toughness of HSS ensures stable performance even under light to moderate loads.

718H (Inconel 718): Machining Inconel 718 is challenging due to its high strength and tendency to work-harden. HSS end mills, with their enhanced wear resistance, can handle these tough materials, though they are generally used in applications requiring moderate cutting speeds and feeds. The right cooling (such as oil mist or water cooling) is often required to reduce heat buildup and improve tool life.

NAK80: This material requires high precision and excellent surface finish, which makes HSS end mills with superior sharpness and edge stability a good choice. These end mills are well-suited for fine machining operations, delivering high-quality surface finishes, which is crucial for applications in mold making.

H13 Tool Steel: HSS end mills perform well on H13 due to their toughness, which helps in maintaining tool integrity during high-temperature operations. These end mills allow for both rough and fine machining with consistent results, especially when paired with proper cooling techniques like water cooling.

3. Factors That Affect Machining Performance

While HSS end mills are versatile, certain factors can influence their performance when machining these materials:

Cutting Speed and Feed Rates: Each material has an optimal cutting speed and feed rate. For softer materials like P20, higher cutting speeds are often possible. For tougher materials like 718H, lower speeds are typically recommended to avoid excessive tool wear and heat generation.

Coolant Selection: The cooling environment plays a key role in tool life. For materials like Inconel 718, using oil mist or high-pressure coolant can significantly extend the tool life by reducing heat buildup. Conversely, for materials like P20 and NAK80, water cooling might be more effective at maintaining the tool’s sharpness and preventing material buildup on the cutting edge.

Tool Rigidity: The rigidity of the cutting tool and the CNC machine plays a significant role in maintaining precision and surface finish. For tough materials like H13, the ability of the tool to remain rigid during high-speed operations ensures that the tool doesn't wear prematurely or create vibrations that would compromise the quality of the part.

4. Advantages of HSS End Mills for Machining Tough Materials

Toughness and Wear Resistance: HSS end mills made with ultra-fine particle substrates (0.4μm) offer a balance of toughness and wear resistance, making them ideal for machining tough materials like 718H and H13.

Long Tool Life: The enhanced design of HSS end mills allows them to handle both rough and fine machining tasks, offering long-term stable performance and reducing the frequency of tool changes.

Versatility: These end mills can be used in a variety of environments, including oil mist, water cooling, and oil cooling, allowing them to excel in both dry and wet cutting applications.

5. Conclusion: The Best Choice for High-Speed Machining of Tool Steels

High-speed steel end mills are a versatile and reliable tool for machining a variety of tough materials like P20, 718H, NAK80, and H13. Their toughness, wear resistance, and stability under high-speed CNC machining conditions make them a solid choice for industries that demand precision and durability. By selecting the right tool, optimizing cutting parameters, and employing proper cooling techniques, manufacturers can maximize productivity and tool life while achieving high-quality results.