Address:

No.233-3 Yangchenghu Road, Xixiashu Industrial Park, Xinbei District, Changzhou City, Jiangsu Province

Reaming is a crucial operation in machining, where a tool known as a reamer is used to improve the size, finish, and tolerance of an existing hole. To achieve optimal results, it's essential to select the correct speeds and feeds for reaming. These parameters play a significant role in enhancing tool life, preventing tool wear, and ensuring high-quality finishes. In this deep guide, we'll explore reamer speeds and feeds in detail, covering the factors that influence them, the best practices for setting them, and how they affect machining performance.

1. Understanding Reamers

Before diving into speeds and feeds, let's first understand what reamers are and how they work. Reamers are rotary cutting tools used to enlarge and finish pre-drilled holes with precision. Unlike drills, which are designed to remove a significant amount of material, reamers are used to fine-tune holes to their exact dimensions and improve surface finish.

There are several types of reamers, including:

Straight reamers: These are commonly used for enlarging and finishing holes with straight edges.

Tapered reamers: Used to create conical holes.

Carbide reamers: Known for their hardness and ability to withstand high temperatures, making them ideal for tough materials.

Each of these reamers requires specific speeds and feeds to maximize their performance.

2. Factors Affecting Reamer Speeds and Feeds

Reamer speeds and feeds are influenced by several factors, including:

Material type: Different materials require different cutting speeds to ensure efficiency and prevent tool wear. Harder materials like steel and titanium typically require slower cutting speeds than softer materials like aluminum or brass.

Reamer material: The material of the reamer itself (high-speed steel, carbide, etc.) determines its cutting speed range. Carbide reamers, for example, can withstand higher speeds compared to high-speed steel reamers.

Hole size and depth: The size and depth of the hole being reamed affect the amount of material being removed, which, in turn, impacts the required speeds and feeds.

Machine rigidity: A stiffer machine allows for higher speeds and feeds without sacrificing tool life or quality.

Coolant usage: The use of coolant reduces heat generation, making it possible to increase speeds and feeds while improving surface finish and prolonging tool life.

3. Speeds: How to Calculate the Right Cutting Speed

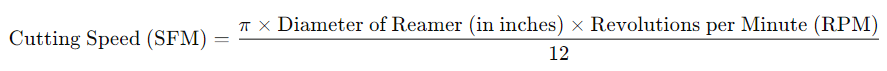

The cutting speed, or surface speed, refers to the speed at which the cutting edge of the reamer moves across the workpiece. It is typically measured in surface feet per minute (SFM) or meters per minute (m/min). To calculate the proper cutting speed for a reamer, use the following formula:

Alternatively, you can use a cutting speed chart for different materials, which provides recommended surface speeds based on the material being machined and the reamer type.

Here are general guidelines for cutting speeds for various materials:

Aluminum: 300-600 SFM

Brass: 100-200 SFM

Carbon Steel: 50-150 SFM

Stainless Steel: 30-100 SFM

Titanium: 10-50 SFM

4. Feeds: How to Determine the Right Feed Rate

Feed rate refers to the rate at which the reamer advances into the workpiece. It is typically measured in inches per minute (IPM) or millimeters per minute (mm/min). The feed rate is a critical factor in determining how much material the reamer removes per pass and plays a crucial role in determining the surface finish and tool life.

The recommended feed rate for reaming is generally lower than that for drilling, as reaming is a finishing operation. The feed rate should also account for the type of reamer, hole size, material, and cutting speed.

A common formula to calculate the feed rate is:

Feed Rate (IPM)=Feed per Tooth (IPT)×Number of Teeth×RPM

Where:

Feed per Tooth (IPT): The amount of material each tooth of the reamer removes with each revolution. This varies based on the material, tool type, and cutting conditions.

Number of Teeth: The number of cutting edges on the reamer.

5. Optimizing Reaming Parameters

Optimizing reamer speeds and feeds can improve overall machining efficiency, reduce costs, and extend tool life. Here are some key considerations for optimizing reaming operations:

5.1. Surface Finish

Slow feeds generally result in a finer surface finish, while faster feeds may produce a rougher finish but allow for faster material removal.

A smoother surface finish is particularly important for applications where high precision is required, such as in aerospace or automotive industries.

5.2. Tool Wear and Life

High cutting speeds can lead to excessive heat buildup, causing premature tool wear.

Optimized feeds ensure that the cutting edges do not become overloaded, which can extend tool life.

Regular monitoring and adjustment of speeds and feeds are necessary to avoid overworking the reamer, especially when working with tough materials.

5.3. Chip Removal

A proper feed rate helps in efficient chip removal. If the feed is too slow, chips may not be cleared effectively, leading to chip packing, which can damage both the tool and workpiece.

Higher feed rates generate larger chips, which need to be efficiently evacuated from the hole to avoid interference with the cutting action.

6. Best Practices for Reamer Speeds and Feeds

To ensure optimal reaming performance, here are some best practices:

Use coolant: Proper coolant use can extend tool life and prevent excessive heat buildup.

Start with conservative settings: If unsure, start with lower speeds and feeds and gradually increase them while monitoring tool wear and surface finish.

Use high-quality reamers: Choose the right type of reamer for the job, whether it's carbide for tough materials or high-speed steel for general use.

Monitor chip formation: Watch the chips as they form during the reaming process. Ideally, they should be small and consistent in shape. Large, stringy chips may indicate an issue with feed rate or cutting speed.

Check machine rigidity: Ensure that the machine setup is stable and free from vibrations, as this can affect the accuracy of reaming and lead to premature tool wear.

7. Common Mistakes to Avoid

Too high feed rate: Using a feed rate that's too high can cause excessive wear on the reamer and compromise hole quality.

Ignoring material hardness: Materials with higher hardness levels require slower cutting speeds and feeds. Using standard settings can result in poor performance.

Not monitoring tool wear: Failing to track tool wear can lead to poor surface finish and dimensional inaccuracies. Always check for signs of wear, such as dull cutting edges or chipped tips.

Inadequate chip removal: If chips aren’t properly cleared, they can pack into the hole, causing damage to both the reamer and the workpiece.

8. Conclusion

Reamer speeds and feeds are critical parameters that affect machining efficiency, tool life, and the quality of the finished product. By understanding the factors influencing these parameters and following best practices, machinists can achieve superior results in reaming operations. With careful consideration of material types, reamer specifications, and machine capabilities, it is possible to optimize reaming operations for both high-quality finishes and maximum tool life.