Address:

No.233-3 Yangchenghu Road, Xixiashu Industrial Park, Xinbei District, Changzhou City, Jiangsu Province

Introduction:

In the world of precision machining, selecting the right method for creating threads is crucial to achieving the best results in terms of strength, surface finish, and overall cost-effectiveness. Among the most common methods used to create threads are thread milling and tapping. While both methods are effective, they each have their advantages, limitations, and best-use scenarios.

In this article, we’ll dive deep into the intricacies of thread milling and tapping, exploring when one method is preferable over the other, and analyzing factors like material properties, thread size, hole depth, and production volume.

1. Understanding the Basics of Thread Milling and Tapping:

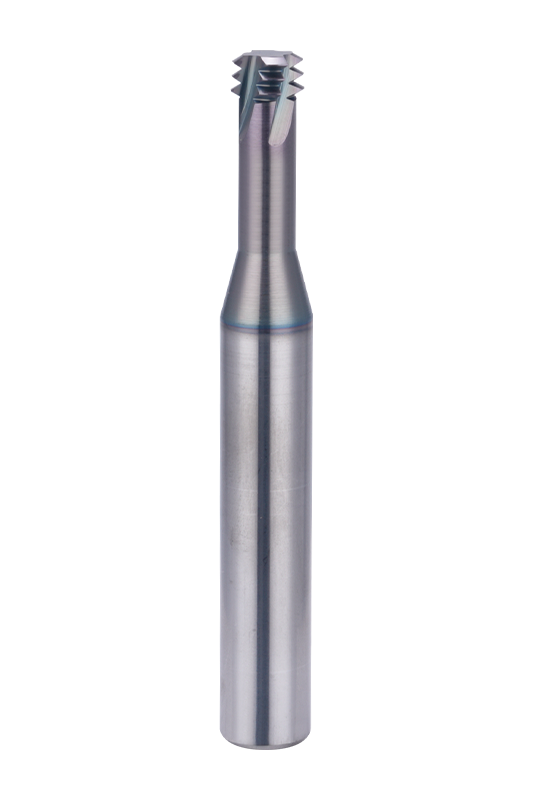

Thread Milling:

Thread milling involves using a rotating cutter to create threads in a hole. The cutter moves along the surface in a helical path, forming the desired thread profile. This process is performed using a CNC milling machine, and the tool typically has multiple cutting edges that engage with the material simultaneously.

Tapping:

Tapping, on the other hand, is a process in which a tapping tool (similar to a drill bit with cutting threads) is used to create internal threads by rotating the tool inside the hole. Tapping is typically done using a CNC lathe or vertical machining center.

2. Key Differences:

2.1. Tooling Requirements:

Thread Milling: Requires a specialized milling cutter with multiple cutting edges, which can create both right- and left-handed threads.

Tapping: Uses a single-point tool that cuts threads directly into the material, and there are different taps for different materials and thread forms.

2.2. Machine Setup and Versatility:

Thread Milling: Offers more versatility as it can be used to create a variety of threads, including larger sizes or custom profiles, on both blind and through holes. It can also be done on a CNC mill, which is more versatile in terms of general machining operations.

Tapping: Typically requires a dedicated tapping cycle, making it somewhat less versatile in terms of setup and customization compared to thread milling.

2.3. Thread Accuracy:

Thread Milling: Typically provides a higher level of accuracy and surface finish because the cutter does not have to engage the material at the same point as a tapping tool. It's also easier to adjust parameters for thread size during the milling process.

Tapping: Tapping may experience slight inaccuracies due to tool wear, especially in hard materials. It can also have issues like tool breakage in deeper holes or irregular threads in challenging materials.

3. Material Considerations:

3.1. Hard Materials (e.g., Stainless Steel, Titanium):

Thread Milling: Ideal for hard materials as it reduces the risk of tool breakage. Thread milling also doesn’t generate as much heat as tapping, which helps maintain tool life and quality.

Tapping: In hard materials, tapping can be slower and more prone to tool breakage. Also, tapping deep holes in hard materials is generally not recommended because of potential tool deflection and failure.

3.2. Soft Materials (e.g., Aluminum, Brass):

Thread Milling: Works well for soft materials but might be slower than tapping due to the multi-cutting-edge nature of the operation.

Tapping: Faster in soft materials, as it’s a more direct process with minimal setup required.

4. Factors Influencing the Decision:

4.1. Thread Size and Depth:

Thread Milling: Works well for larger threads (above 1/2” in diameter) and deep threads. It’s especially effective for creating internal threads that are deeper than the length of a typical tap.

Tapping: Best suited for shallow threads, generally under 1” in diameter. The deeper the thread, the more likely tapping will cause issues like tap breakage or thread deformation.

4.2. Cycle Time and Production Volume:

Thread Milling: The cycle time is generally longer due to the process’s complexity, and while it can be optimized with multi-tooth cutters, it’s not as fast as tapping in many cases. However, in low-volume or custom runs, it may be the better option due to its versatility.

Tapping: Tapping tends to be faster in high-volume production when making threads in shallow holes with a small diameter. The faster tool engagement allows quicker threading, especially for industries requiring large quantities of parts.

4.3. Chip Control:

Thread Milling: Thread milling produces continuous, manageable chips, reducing the risk of chip buildup and allowing for better heat dissipation.

Tapping: Can produce short, broken chips, which may become trapped in the hole and lead to issues like chip packing or tool clogging. Special care must be taken to ensure chip evacuation, especially in deeper holes.

5. Advantages of Thread Milling:

Versatility: Thread milling can create a wide variety of thread forms, including non-standard and oversized threads.

Precision: Higher accuracy, especially for larger or deeper threads.

Tool Life: Tools last longer due to the less aggressive cutting action.

No Need for Pre-drilled Holes: Thread milling is not dependent on the size of the hole, which allows for greater flexibility in hole sizes.

Multi-tasking Capability: A CNC milling machine can be used for other operations, such as facing, drilling, or contour milling, which increases efficiency.

6. Advantages of Tapping:

Speed: Tapping is a fast process, particularly for shallow threads in soft materials.

Simplicity: The setup and tooling are relatively simple and cost-effective compared to thread milling.

Lower Tooling Costs: Tapping tools are generally cheaper than thread mills, making it more economical for high-volume, shallow-thread applications.

Consistency: In high-volume production runs, tapping tends to be more consistent in thread formation and is easier to automate.

7. Applications Best Suited for Thread Milling:

Large Thread Sizes: Thread milling is ideal for larger threads (over 1/2”) or high-precision applications.

Deep or Blind Holes: When dealing with deep holes, thread milling allows for better control over tool deflection and threading accuracy.

Hard-to-machine Materials: Thread milling is often the go-to method for difficult materials like high-strength steel, stainless steel, and titanium.

Complex Thread Forms: Thread milling can easily create non-standard or custom thread profiles, making it ideal for niche applications.

8. Applications Best Suited for Tapping:

Small, Shallow Threads: Tapping is effective for making small and shallow threads in soft-to-medium materials.

High-Volume Production: When you need to produce a large number of threaded parts quickly, tapping is often the more economical choice.

Simple Thread Requirements: For straightforward, standard threads, tapping is efficient and cost-effective.

Conclusion:

In conclusion, both thread milling and tapping have their respective benefits and limitations. The choice between the two methods depends on several factors, including material hardness, thread size, hole depth, production volume, and thread quality requirements.

For larger, deeper, and high-precision threads, thread milling is often the superior choice.

For smaller, shallower threads in softer materials, tapping remains a reliable and faster option.