Address:

No.233-3 Yangchenghu Road, Xixiashu Industrial Park, Xinbei District, Changzhou City, Jiangsu Province

Introduction

Tungsten steel and tungsten carbide are often confused due to their similar names and the fact that both are used in heavy-duty, high-performance applications. However, they have distinct characteristics, chemical compositions, and properties that make them suitable for different industries. This article will delve deep into these two materials, exploring their differences, uses, and why one might be chosen over the other for specific applications.

1. What is Tungsten Steel?

Tungsten steel, often referred to as high-speed steel (HSS), is a blend of tungsten and iron alloy with varying amounts of other elements like carbon, chromium, vanadium, and molybdenum. The primary ingredient, tungsten, is known for its hardness, high melting point, and durability, which enhances the steel’s resistance to wear and heat.

Composition of Tungsten Steel:

Tungsten (W): Typically comprises about 18-20% of the alloy, contributing to hardness and heat resistance.

Iron (Fe): Acts as the base material.

Chromium (Cr): Provides additional corrosion resistance.

Vanadium (V): Improves the toughness of the alloy.

Molybdenum (Mo): Enhances high-temperature strength.

Properties of Tungsten Steel:

Hardness: While not as hard as tungsten carbide, tungsten steel is highly durable and resistant to wear.

Heat Resistance: The material maintains its properties at elevated temperatures, making it useful in machining processes that generate heat.

Toughness: Tungsten steel can withstand high stresses and strains without fracturing, giving it a long service life.

Machinability: Compared to tungsten carbide, tungsten steel is easier to machine and shape.

Applications of Tungsten Steel:

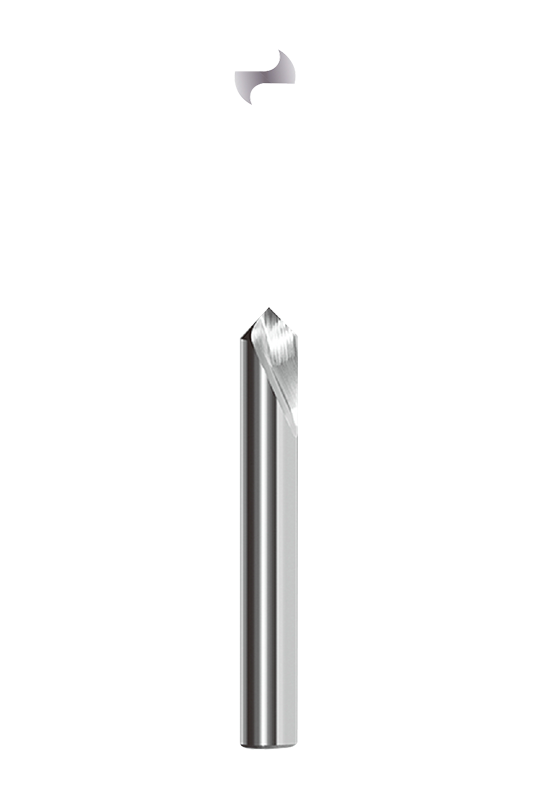

Cutting Tools: Such as drills, saw blades, and milling cutters.

Tooling Equipment: Used in industries like aerospace and automotive for machining high-strength materials.

Industrial Machinery: Components that require high-speed operations and resistance to heat.

2. What is Tungsten Carbide?

Tungsten carbide (WC) is a chemical compound made from tungsten and carbon. It is known for being one of the hardest materials on Earth, second only to diamond. Tungsten carbide’s properties make it ideal for applications where wear resistance and hardness are crucial, such as in mining and manufacturing tools.

Composition of Tungsten Carbide:

Tungsten (W): Typically makes up 80-90% of the compound.

Carbon (C): The remaining 10-20%, combined with tungsten to form the carbide compound.

Properties of Tungsten Carbide:

Extreme Hardness: Tungsten carbide is incredibly hard, with a hardness level close to that of diamond, which makes it excellent for cutting, grinding, and drilling.

Wear Resistance: Its superior hardness and wear resistance make it the preferred material for high-impact and abrasive environments.

Brittleness: While very hard, tungsten carbide is more brittle than tungsten steel. This brittleness makes it prone to cracking or shattering under extreme stress or impact.

Density: Tungsten carbide has a very high density, which makes it ideal for applications where weight is a factor (such as in counterweights or ballast).

Applications of Tungsten Carbide:

Cutting Tools: Used in industrial drills, end mills, reamers, and inserts.

Mining and Oil Drilling: Tungsten carbide is widely used for drill bits and tools in mining and oil extraction because of its resistance to abrasion.

Aerospace and Military: It is used for manufacturing jet engine components, armor-piercing ammunition, and other specialized parts that require durability and hardness.

Jewelry: Tungsten carbide’s scratch resistance and hardness make it a popular choice for wedding bands and other jewelry items.

3. Key Differences Between Tungsten Steel and Tungsten Carbide

Now that we understand the individual characteristics of tungsten steel and tungsten carbide, let's compare them across various factors:

Hardness

Tungsten Steel: While hard, tungsten steel is not as hard as tungsten carbide. Its hardness makes it suitable for many industrial applications, but it cannot compete with tungsten carbide in terms of sheer hardness.

Tungsten Carbide: One of the hardest materials known to man, tungsten carbide is far superior in hardness compared to tungsten steel. Its hardness allows it to perform well in high-wear and high-impact applications.

Brittleness

Tungsten Steel: Tungsten steel is more flexible and ductile compared to tungsten carbide. This flexibility allows it to absorb more stress without breaking.

Tungsten Carbide: Tungsten carbide, though incredibly hard, is more brittle and susceptible to cracking under high impact or stress.

Density

Tungsten Steel: Tungsten steel has a lower density than tungsten carbide, making it lighter and easier to handle in some cases.

Tungsten Carbide: Tungsten carbide is much denser, which is beneficial in applications requiring high weight or mass, such as counterweights or ballast.

Machinability

Tungsten Steel: Tungsten steel is easier to machine compared to tungsten carbide, which can be challenging to process due to its extreme hardness.

Tungsten Carbide: Due to its hardness, tungsten carbide is difficult to machine and often requires specialized equipment and processes for shaping and finishing.

Cost

Tungsten Steel: Tungsten steel is typically less expensive than tungsten carbide, making it a more cost-effective choice for many industrial applications.

Tungsten Carbide: Tungsten carbide is much more expensive due to its superior hardness, density, and wear resistance.

4. Choosing the Right Material for Your Application

Both tungsten steel and tungsten carbide have unique benefits and are suited for different applications. When choosing between the two, it’s important to consider factors such as:

Application Type: For cutting, grinding, or drilling in hard materials, tungsten carbide is often the better choice. For general industrial tooling, where flexibility and toughness are more important, tungsten steel is a solid option.

Impact Resistance: If your application involves a lot of impact or stress, tungsten steel may be better due to its toughness and ability to absorb shock.

Wear Resistance: If you require materials that can withstand extreme wear and abrasion, tungsten carbide is unmatched.

Cost Considerations: Tungsten steel offers a more cost-effective solution when budget is a concern, while tungsten carbide is more expensive but offers superior performance in high-stress environments.

5. Conclusion

Both tungsten steel and tungsten carbide are indispensable in modern industry, each excelling in its own right. Tungsten steel is a versatile material that balances hardness, toughness, and machinability, making it ideal for general tooling and high-speed operations. On the other hand, tungsten carbide’s unmatched hardness and wear resistance make it the material of choice for heavy-duty, high-impact, and abrasive environments, although it comes with the tradeoff of brittleness and higher cost.

Understanding the properties and differences between these two materials will help you choose the right one for your specific needs, ensuring optimal performance and longevity of your tools and components.