Address:

No.233-3 Yangchenghu Road, Xixiashu Industrial Park, Xinbei District, Changzhou City, Jiangsu Province

ZHENLONG FOCUS ON THE DEMAND, STRIVING FOR PURSUING INNOVATION

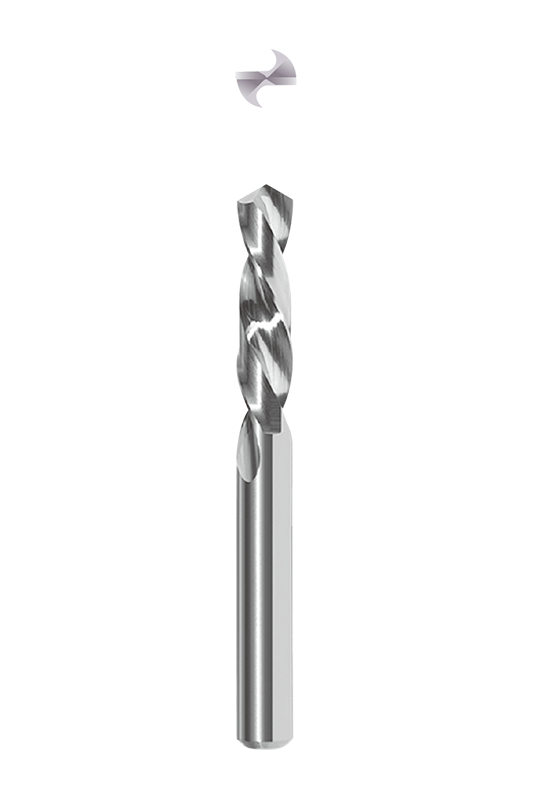

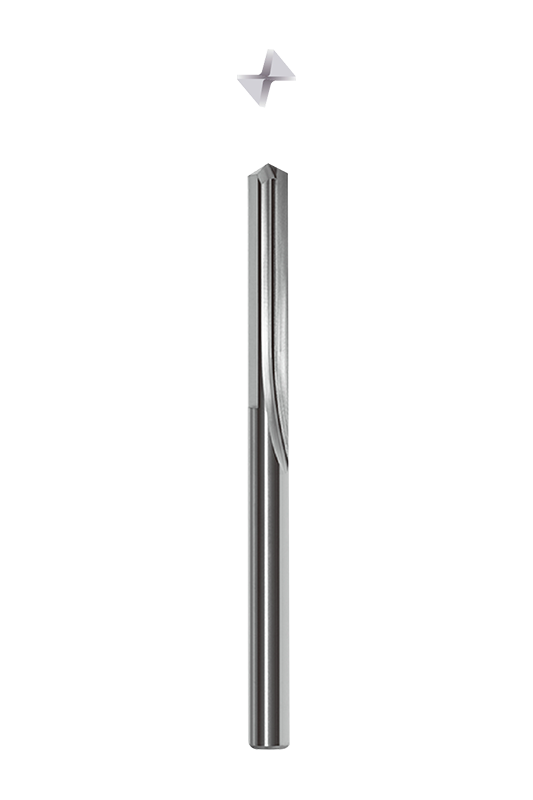

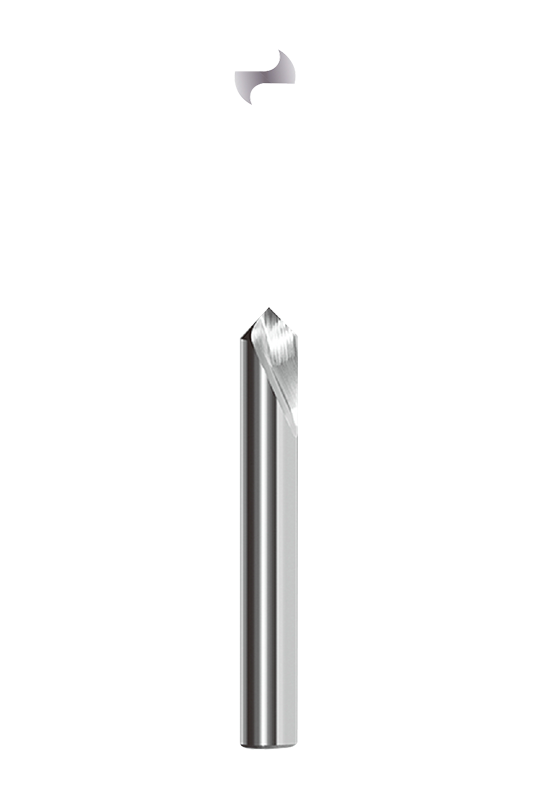

Solid carbide drill bits is a high-performance drilling tool made of carbide material with high hardness, wear resistance and heat resistance, suitable for processing various high-hardness materials such as stainless steel, titanium alloy, hardened steel, composite materials, etc. It performs well in precision machining and high-efficiency drilling, and is widely used in aerospace, automobile manufacturing, mold processing and other fields.

Solid Carbide 3 Flute Drill Bits for cast iron and aluminum alloy machining

Straight Flute Drills for Cast Iron and Aluminum Alloy Machining

Carbide Spot Drill for Cast Iron and Aluminum Alloy Machining

Enterprise establishment

Employees

Changzhou Maton Tools Co.,Ltd. is located in the economically developed Yangtze River Delta region.The factory is located in XixiashuHigh-tech Development Zone,a well-known tool town in China. We are Solid Carbide Drill Bits Manufacturers in China. It is adjacent to S239 and Jiangyi Expressway in the east,25kilometers away from Changzhou North Station of the high-speed railway, and G42 Shanghai-Nanjing in the south.High-speed,8 kilometers away from Changzhou Benniu International Airport,the transportation is very convenient.

As Solid Carbide Drill Bits Company, Magotantools take the ISO9001 quality system as the standard,under the guidanceof the business philosophy of"zero defect in products"and"zero distance in service",based on the spirit of"integrity","unity"and"exploita- tion",and follow a fair and just company style for management.Product production adopts five-axisand six-axis CNC grinding and machining centers from Germany,Switzerland,Japan,etc.,and is equipped with high-precision testing equipment such as Germany,Japan,and China,so as to meet the needs of production with high quality and quantity.

The company's team consists of 2 professor-level senior engineers in China,and has more than ten experienced tool technology and R&D personnel.It has formed a long-term cooperation model with East China University of Science and Technology,and continuously develops various high-performance CNC tools,and has won various national awards. Supply Wholesale Solid Carbide Drill Bits. More than 10 patents,the company's products are mainly used in the defense industry, aerospace industry,automotive industry,electronic products and molds and other fields.

The company's various products are recognized and favored by well-known domestic companies.With infinite technology,infinite creation,and pursuit of excellence,Magotan tools will write future prosperity and dreams with more extraordinary confidence and high-quality quality.

Solid Carbide Drill Bits for Stainless Steel, Titanium Alloy, and Hardened Steel Machining

Solid carbide drill bits are widely recognized as indispensable tools for modern precision machining, especially in demanding industries that involve stainless steel, titanium alloys, and hardened steels. These materials, known for their exceptional strength and resistance to deformation, pose significant challenges during drilling operations. Solid carbide tools, with their superior hardness, heat resistance, and wear resistance, are specifically engineered to meet these challenges and deliver consistently high performance even under extreme working conditions.

One of the key advantages of solid carbide drill bits is their ability to maintain dimensional stability and edge sharpness at high cutting speeds. This characteristic makes them particularly effective in high-efficiency CNC machining applications, where consistent accuracy and long tool life are essential. Whether it's for deep-hole drilling in stainless steel or precision holes in aerospace-grade titanium, solid carbide bits offer the strength and reliability necessary for efficient operations with minimal tool replacement.

The aerospace, automotive, and mold manufacturing sectors heavily rely on these drill bits due to their capability to handle high-hardness materials without compromising surface finish or tolerance. In industries where time and precision are critical, solid carbide tools support streamlined workflows and improved productivity. Their compatibility with advanced machining centers ensures that even complex components can be produced with reduced cycle times and lower per-unit tooling costs.

A key player in the development and supply of these high-performance tools is Magotan Tools, under Changzhou Maiteng Tools Co., Ltd., located in the Yangtze River Delta region of China. Strategically situated in Xixiashu High-tech Development Zone—an area renowned for precision tooling—the company benefits from a robust transportation network and industrial infrastructure that supports efficient production and distribution.

Magotan Tools combines advanced manufacturing capabilities with a strong technical foundation. The company’s production facilities utilize German, Japanese, and Swiss five-axis and six-axis CNC grinding machines to ensure precise geometries and repeatable quality. High-precision testing instruments further reinforce the reliability of every finished product, allowing the company to meet the strict demands of customers across different sectors.

Innovation is central to Magotan’s growth. With a dedicated team that includes senior engineers and experienced R&D personnel, the company maintains long-term technical collaborations with leading institutions such as East China University of Science and Technology. Through continuous research and patent development, Magotan has positioned itself as a forward-thinking manufacturer that integrates scientific advancement with practical tool design.

The solid carbide drill bits produced by Magotan Tools are the result of both technological expertise and a commitment to quality. Built to ISO9001 standards and aligned with a management philosophy that emphasizes product excellence and responsive service, the company has established itself as a trusted partner in both domestic and international markets. Its products are already in use by major clients in sectors ranging from defense to consumer electronics, gaining recognition for their durability and consistent performance.

Solid carbide drill bits represent a vital solution for precision drilling in stainless steel, titanium alloy, and hardened steel. Backed by modern manufacturing, skilled engineering, and a deep understanding of end-user needs, Magotan Tools delivers a product that meets the evolving demands of high-performance industries. Whether in aerospace, automotive, or mold production, their tools help manufacturers achieve better results, faster turnaround, and greater long-term value.