Address:

No.233-3 Yangchenghu Road, Xixiashu Industrial Park, Xinbei District, Changzhou City, Jiangsu Province

• Four-edge design: With four cutting edges, it can provide higher cutting efficiency at the same speed compared to double-edge or three-edge milling cutters.

• Rough skin processing: Suitable for rough processing, large cutting volume, high surface roughness, suitable for material removal before subsequent finishing.

• Universal milling cutter is suitable for heat treatment of a full range of steel materials, U-groove structure design, suitable for roughing and finishing.

• It is also suitable for the processing of non-steel and aluminum materials, with complete specifications and models, and a wide range of uses.

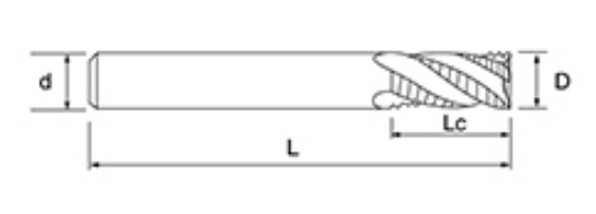

| No. |

Diameter D |

Flute Length Lc |

Overall Length L |

Shank Dia d |

Blade Count F |

| NNC-4TW-D6 | 6 | 16 | 50 | 6 | 4 |

| NNC-4TW-D8 | 8 | 20 | 60 | 8 | 4 |

| NNC-4TW-D10 | 10 | 25 | 75 | 10 | 4 |

| NNC-4TW-D12 | 12 | 30 | 75 | 12 | 4 |

| NNC-4TW-D14 | 14 | 35 | 100 | 14 | 4 |

| NNC-4TW-D16 | 16 | 45 | 100 | 16 | 4 |

| NNC-4TW-D18 | 18 | 45 | 100 | 18 | 4 |

| NNC-4TW-D20 | 20 | 45 | 100 | 20 | 4 |

| Tool Series | Diameter | Radius | Corner Radius | Flute Length | Effective Length | Overall Length | Shank Dia | |||

| D | R | CR | Lc | L1 | L | d | ||||

|

NNC Universal Carbide Milling Cutters |

D0.1~D0.9 | +0 -0.005 |

R0.05~R2 | +/-0.005 | CR0.05~CR0.5 | +/-0.005 | +0 +0.2 |

+0 +0.3 |

+0 +0.5 |

h5 |

| D1.0~D4.0 | +0 -0.008 |

+0 +0.3 |

+0 +0.5 |

|||||||

| D1.0~D3.5 | +0 -0.008 |

R0.5~R1.75 | +/-0.005 | CR0.1~CR0.5 | +/-0.005 | +0 +0.3 |

+0 +0.5 |

+0 +0.5 |

h6 | |

| D4.0~D11.0 | +0 -0.012 |

R2.0~R5.0 | +/-0.008 | CR1.0~CR3.0 | +/-0.008 | +0 +0.5 |

||||

| D12.0~D20.0 | +0 -0.015 |

R6.0~R10.0 | +/-0.01 | |||||||

The NNC-4TW 4 Flute Rough Milling Cutter is available in a variety of specifications from 6mm to 20mm in diameter, with different blade lengths such as 16mm, 20mm, 25mm, 30mm, 40mm and 45mm, allowing users to flexibly combine and use according to processing needs, and adapt to different types of machine tools and working conditions. Such a diverse size scheme has higher applicability in roughing and can effectively improve production efficiency.

Its special shape design retains sufficient cutting space on the blade, and optimizes the geometry of the chip groove to ensure that the chips can be discharged smoothly. The precisely calculated cutting edge can smoothly cut into the workpiece, reduce cutting vibration and improve the stability of roughing. It is designed for rapid material removal and is suitable for the roughing stage.

The tool uses the latest chromium-aluminum composite coating and high-precision grinding process, which not only improves the hardness and wear resistance of the tool, but also effectively reduces the heat accumulation during the cutting process. The smooth coating surface further reduces friction, allowing the tool to maintain an excellent service life during high-speed cutting, reducing the frequency of tool changes and improving overall processing efficiency.

NNC-4TW four flute rough milling cutter is suitable for machining steel, stainless steel, cast iron and other metal materials with hardness within HRC45. Whether it is rough machining on traditional machine tools or modern CNC equipment, it can show reliable level in stability and durability, bringing you efficient production experience.

Enterprise establishment

Employees

Changzhou Maton Tools Co.,Ltd. is located in the economically developed Yangtze River Delta region.The factory is located in XixiashuHigh-tech Development Zone,a well-known tool town in China. We are 4 Flute Rough Milling Cutter Manufacturers.

Magotantools take the ISO9001 quality system as the standard,under the guidanceof the business philosophy of"zero defect in products"and"zero distance in service",based on the spirit of"integrity","unity"and"exploita- tion",and follow a fair and just company style for management.Product production adopts five-axisand six-axis CNC grinding and machining centers from Germany,Switzerland,Japan,etc.,and is equipped with high-precision testing equipment such as Germany,Japan,and China,so as to meet the needs of production with high quality and quantity.

The company continuously develops various high-performance CNC tools, and has won various national awards. Professional 4 Flute Rough Milling Cutter Company. More than 10 patents,the company's products are mainly used in the defense industry, aerospace industry,automotive industry,electronic products and molds and other fields.

The company's various products are recognized and favored by well-known domestic companies.With infinite technology,infinite creation,and pursuit of excellence,Magotan tools will write future prosperity and dreams with more extraordinary confidence and high-quality quality.

We will reply to you within 12 hours after receiving the inquiry on weekdays.

We are manufacturers, we produce and sell ourselves.

We mainly produce tungsten steel milling cutters, drill bits and other hard alloy tools. Professional 4 Flute Rough Milling Cutter Manufacturers.

Our products cover almost the entire mold industry, defense industry, aerospace industry, automotive industry, electronic products and other fields.

Yes, our main focus is on customized products. We develop and produce products based on the drawings or samples provided by customers. Custom 4 Flute Rough Milling Cutter.

We have over 30 units of WALTER from Germany, Makino from Japan, ROLLMATIC from Switzerland, and TTB from Switzerland, with an annual output value of 80 million RMB. We are 4 Flute Rough Milling Cutter Company

Firstly, after each process, we conduct corresponding inspections. For the final product, we will conduct 100% full inspection according to customer requirements and international standards;

Then, we have the advanced and complete top-notch testing equipment in the industry, such as spectral analyzers, metallographic microscopes, etc., which can ensure the stability and consistency of cutting tools, while meeting customers' high-precision testing requirements for cutting tools.

When quoting, we will confirm with you the transaction method, FOB, CIF, CNF or other options. When producing in bulk, we usually make a 30% advance payment first, and then pay the remaining balance upon presentation of the bill of lading. We mostly use T/T as the payment method, but L/C is also acceptable.