Address:

No.233-3 Yangchenghu Road, Xixiashu Industrial Park, Xinbei District, Changzhou City, Jiangsu Province

ZHENLONG FOCUS ON THE DEMAND, STRIVING FOR PURSUING INNOVATION

A thread milling cutter is a cutting tool used to process threads. It cuts internal or external threads on a workpiece by milling. Compared with traditional thread processing methods (such as tapping or turning threads), thread milling cutters have higher flexibility, efficiency, and precision, and are particularly suitable for processing large-diameter threads, difficult-to-process materials, and complex workpieces.

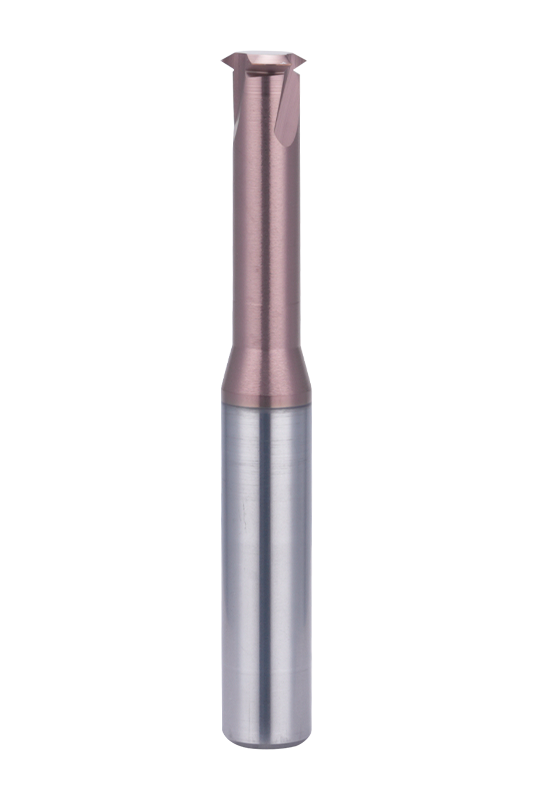

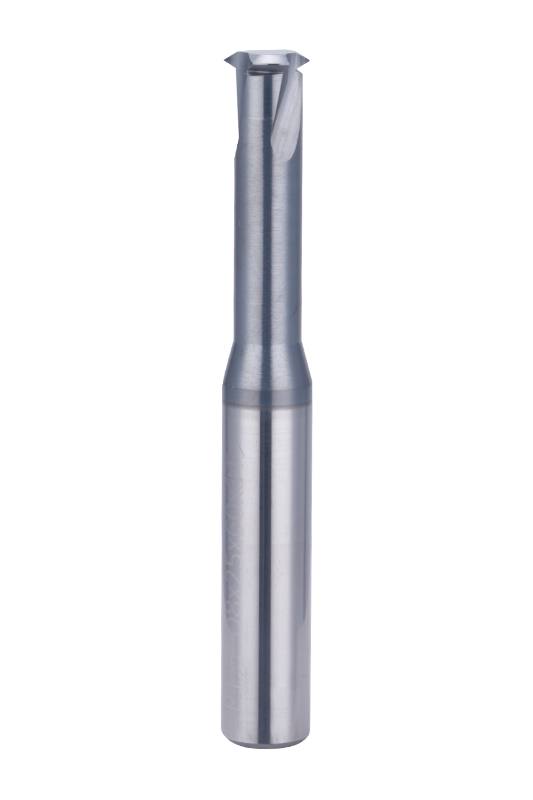

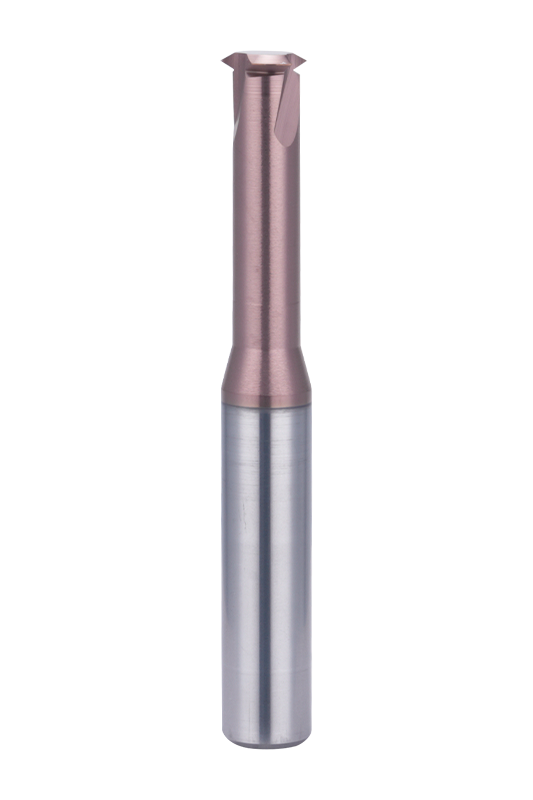

60°UN ANSI/ASME B1.1 Standard Single Tooth Thread Milling Cutter

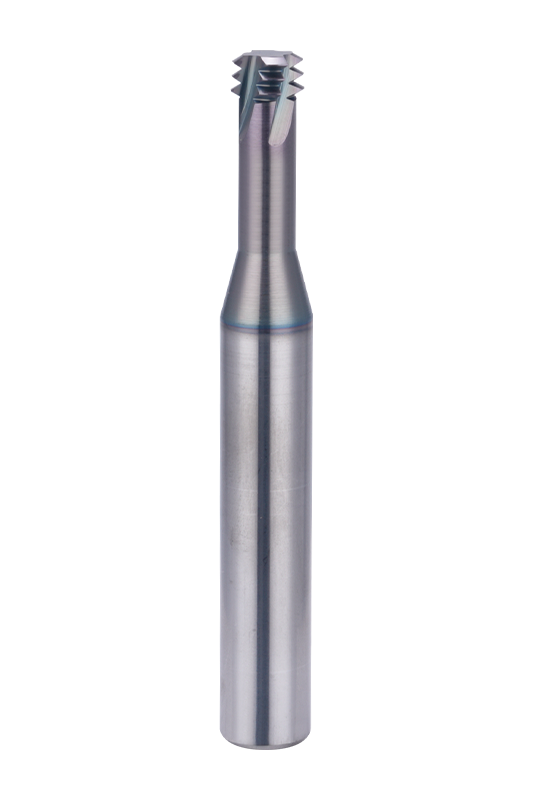

60°UN ANSI/ASME B1.1 Standard Full Tooth Thread Milling Cutter

Enterprise establishment

Employees

Changzhou Maton Tools Co.,Ltd. is located in the economically developed Yangtze River Delta region.The factory is located in XixiashuHigh-tech Development Zone,a well-known tool town in China. We are Thread Milling Cutters Manufacturers in China. It is adjacent to S239 and Jiangyi Expressway in the east,25kilometers away from Changzhou North Station of the high-speed railway, and G42 Shanghai-Nanjing in the south.High-speed,8 kilometers away from Changzhou Benniu International Airport,the transportation is very convenient.

As Thread Milling Cutters Company, Magotantools take the ISO9001 quality system as the standard,under the guidanceof the business philosophy of"zero defect in products"and"zero distance in service",based on the spirit of"integrity","unity"and"exploita- tion",and follow a fair and just company style for management.Product production adopts five-axisand six-axis CNC grinding and machining centers from Germany,Switzerland,Japan,etc.,and is equipped with high-precision testing equipment such as Germany,Japan,and China,so as to meet the needs of production with high quality and quantity.

The company's team consists of 2 professor-level senior engineers in China,and has more than ten experienced tool technology and R&D personnel.It has formed a long-term cooperation model with East China University of Science and Technology,and continuously develops various high-performance CNC tools,and has won various national awards. Supply Wholesale Thread Milling Cutters. More than 10 patents,the company's products are mainly used in the defense industry, aerospace industry,automotive industry,electronic products and molds and other fields.

The company's various products are recognized and favored by well-known domestic companies.With infinite technology,infinite creation,and pursuit of excellence,Magotan tools will write future prosperity and dreams with more extraordinary confidence and high-quality quality.

Advantages of Thread Milling Cutters Over Traditional Threading Methods

In modern manufacturing, the demand for precision, flexibility, and efficiency has driven the evolution of thread processing technologies. Thread milling cutters have emerged as a superior alternative to traditional threading methods such as tapping or turning threads, offering distinct advantages that benefit a wide range of industries.

Enhanced Flexibility and Precision

Thread milling cutters enable the processing of both internal and external threads through a milling operation, allowing for exceptional control over thread geometry. Unlike tapping, which relies on rigid tool paths and can be prone to breakage in challenging materials, thread milling provides higher flexibility in tool movement. This flexibility results in improved precision and surface finish, particularly important when dealing with complex or large-diameter threads.

The milling process also allows for easy adjustment of thread parameters without changing tools, which reduces downtime and increases production efficiency. These attributes make thread milling cutters especially suitable for difficult-to-machine materials such as titanium alloys, stainless steel, and hardened steels, which pose challenges to conventional threading.

Efficiency in Processing Large and Complex Workpieces

Traditional threading techniques often struggle with large-diameter threads or workpieces with intricate geometries. Thread milling cutters excel in these scenarios, as their milling action can handle complex contours and sizes more effectively. This efficiency leads to reduced cycle times and lower tool wear, contributing to cost savings and higher throughput.

Advanced Manufacturing Technology for Superior Tools

The quality of thread milling cutters is critical to maximizing these advantages. Leading manufacturers invest heavily in state-of-the-art CNC machining and grinding centers from global technology leaders, ensuring that tools meet the highest standards of precision and durability. For example, advanced five-axis and six-axis machining equipment allow for the production of cutters with complex geometries and tight tolerances.

In addition to sophisticated machinery, rigorous quality control protocols, including high-precision testing equipment, ensure consistency and reliability in every tool produced. This combination of cutting-edge technology and quality management is essential to delivering thread milling cutters that perform optimally in demanding industrial environments.

Industry Expertise and Innovation

A successful thread milling cutter manufacturer typically maintains a strong focus on research and development. Collaboration with academic institutions and employing experienced engineers enable continuous innovation in tool design and performance. This approach not only results in patented technologies but also keeps manufacturers at the forefront of evolving industry requirements.

Tools designed with a commitment to integrity and continuous improvement gain recognition in sectors such as aerospace, automotive, electronics, and defense, where thread quality and tool reliability are non-negotiable. These industries demand tools capable of meeting stringent specifications and operating under harsh conditions, further highlighting the benefits of thread milling technology.

Strategic Location and Logistics Support

Manufacturers located in economically vibrant regions with excellent transportation infrastructure benefit from efficient supply chains and timely delivery. Proximity to high-speed railways, expressways, and international airports enables companies to serve both domestic and global markets effectively, ensuring that customers receive high-quality thread milling cutters promptly.

Thread milling cutters offer numerous advantages over traditional threading methods, including greater flexibility, precision, and efficiency. Their suitability for large diameters, complex shapes, and challenging materials positions them as the preferred choice in advanced manufacturing applications. Supported by sophisticated manufacturing processes, strong R&D, and a commitment to quality, thread milling cutters represent the future of thread processing across multiple industries.