Address:

No.233-3 Yangchenghu Road, Xixiashu Industrial Park, Xinbei District, Changzhou City, Jiangsu Province

ZHENLONG FOCUS ON THE DEMAND, STRIVING FOR PURSUING INNOVATION

Are there many difficulties in milling copper electrodes? Choose it worry free.

High precision: High precision tolerances ensure the machining requirements of ultra-high copper electrodes are met.

High eficiency: With its special sharp blade design and 0.2μm ultra-ine particle substrate, high-speed processing can be achieved.

Achieving high-qualitly machining surfaces: Compared to traditional coated milling cuters, the use of the latest DLC coating technology significantly improves the tool's lifespan and surface smoothness.

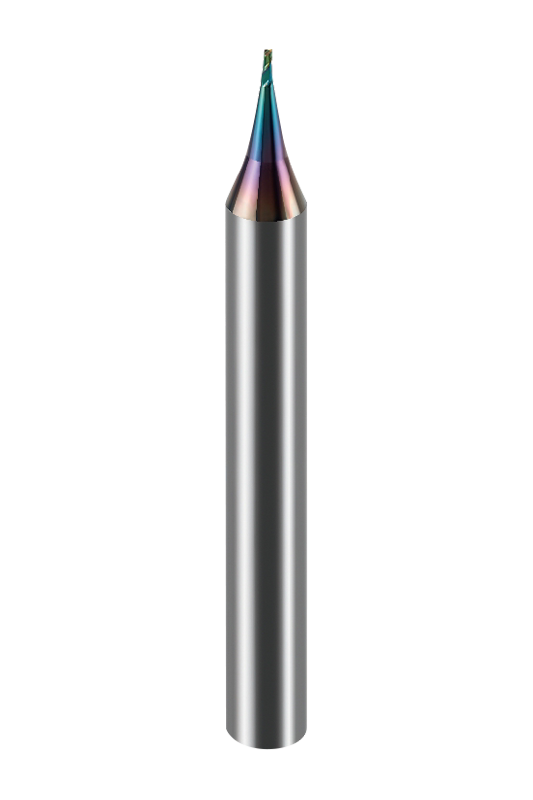

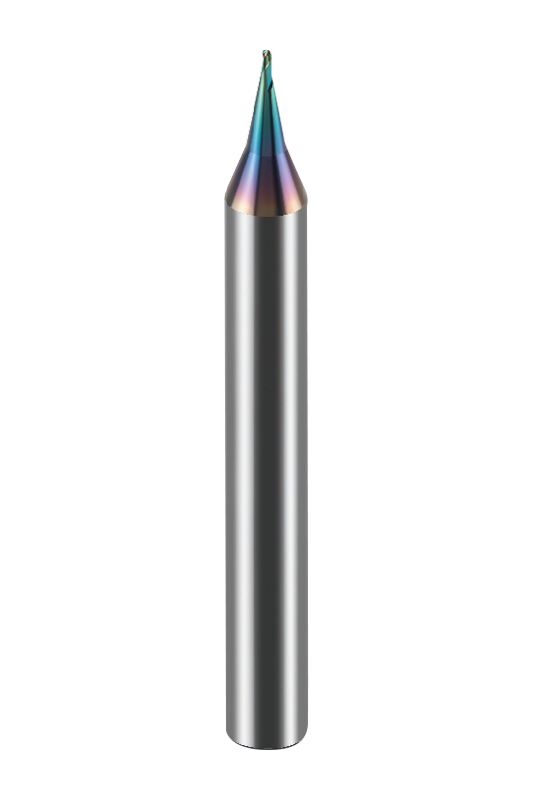

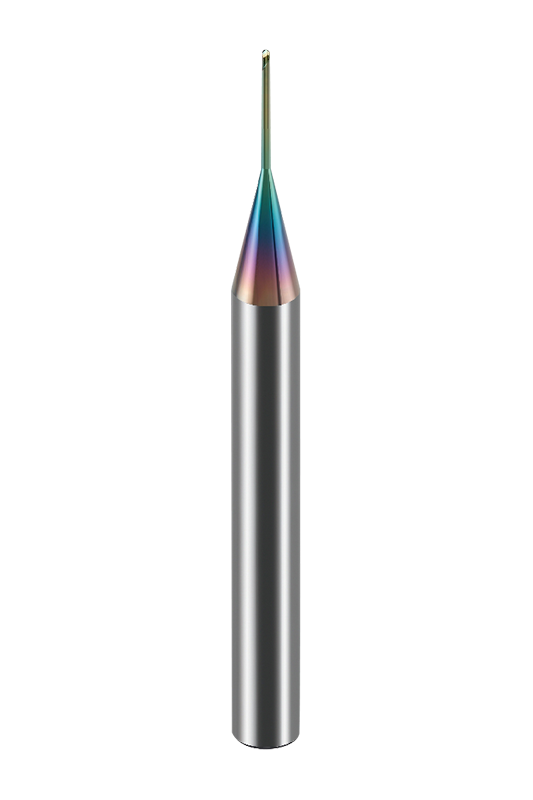

2 Flute Micro Diameter End Mills For Copper Electrode Milling

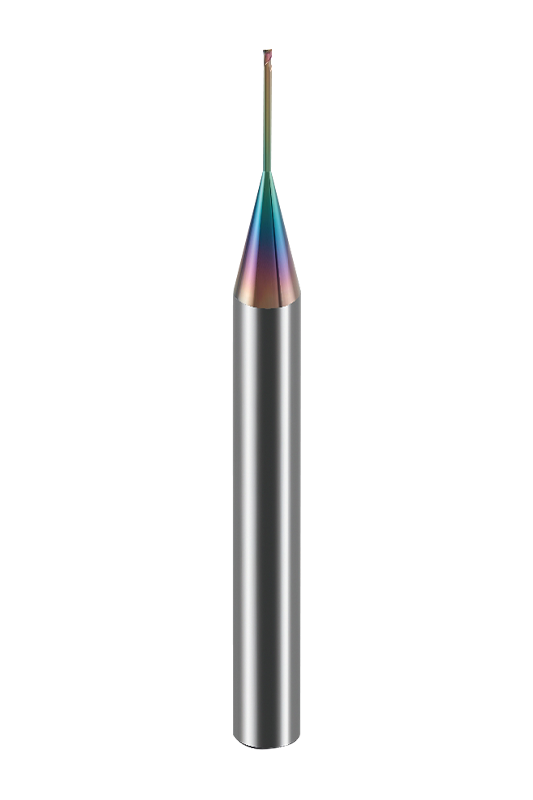

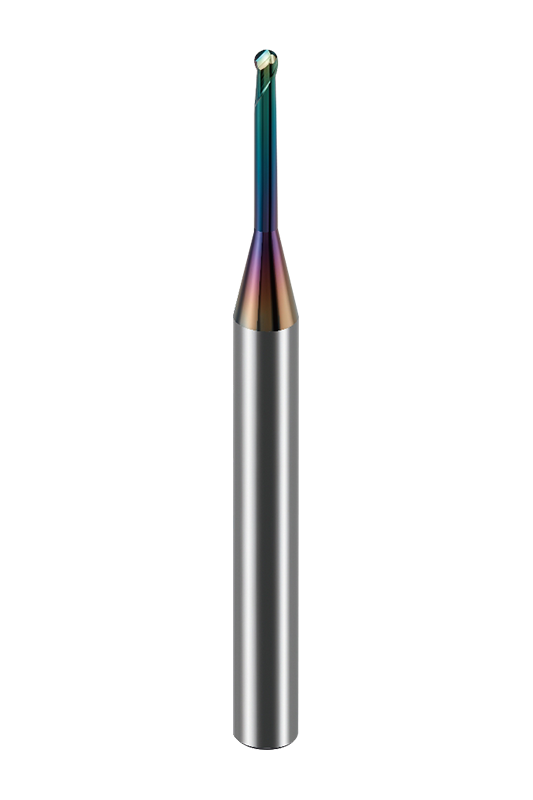

Copper Electrode Machining 2 Flute Micro Diameter Deep Groove End Mills

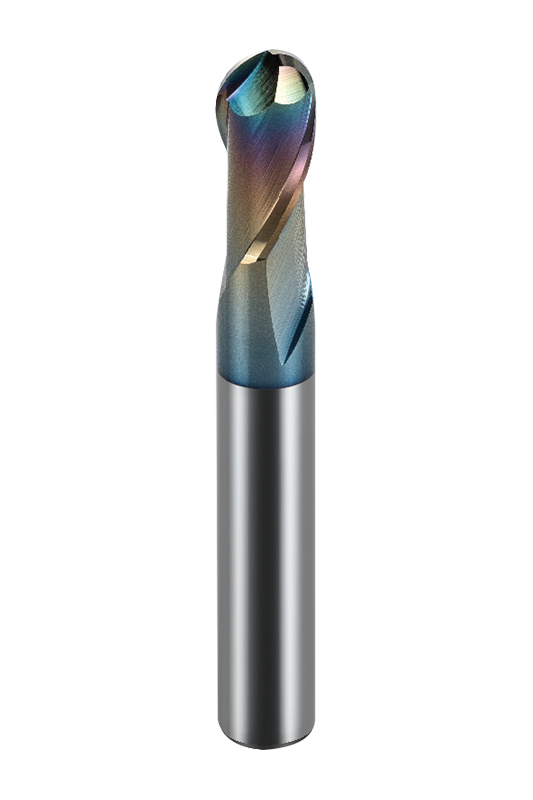

2 Flute Micro Diameter Ball End Copper Electrode Milling Cutters

2 Flute Micro Diameter Deep Groove Ball End Mills For Copper Electrode Milling

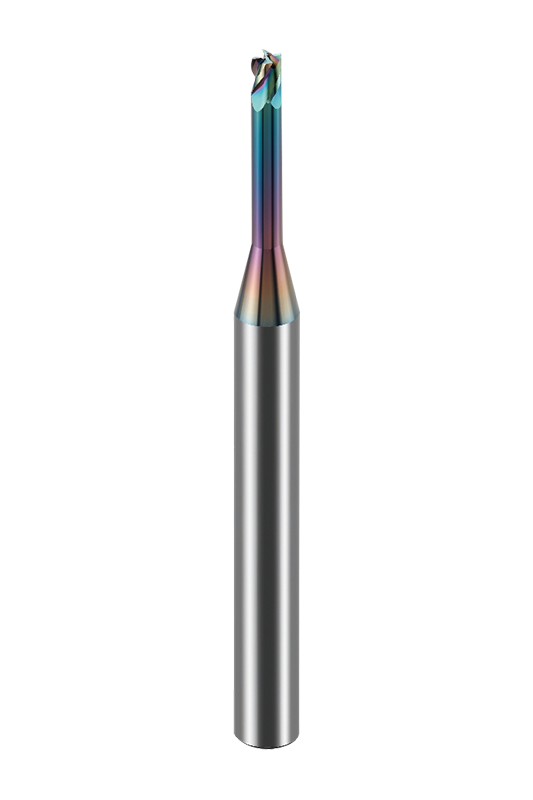

2 Flute Deep Groove Ball End Copper Electrode Milling Cutters

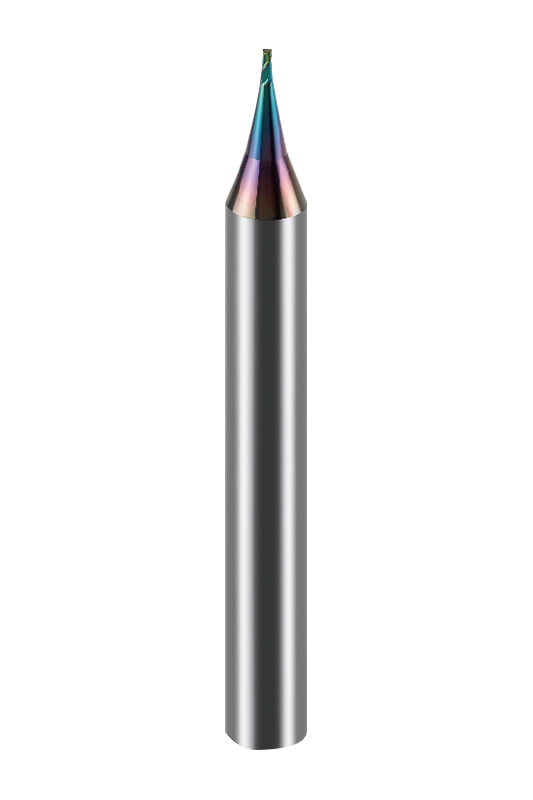

2 Flute Micro Diameter Round Nose End Mills for Copper Electrode Machining

Enterprise establishment

Employees

Changzhou Maton Tools Co.,Ltd. is located in the economically developed Yangtze River Delta region.The factory is located in XixiashuHigh-tech Development Zone,a well-known tool town in China. We are Manufacturers of NNX Carbide End Mills for Copper Electrode in China. It is adjacent to S239 and Jiangyi Expressway in the east,25kilometers away from Changzhou North Station of the high-speed railway, and G42 Shanghai-Nanjing in the south.High-speed,8 kilometers away from Changzhou Benniu International Airport,the transportation is very convenient.

As Wholesale Company of NNX Carbide End Mills for Copper Electrode, Magotantools take the ISO9001 quality system as the standard,under the guidanceof the business philosophy of"zero defect in products"and"zero distance in service",based on the spirit of"integrity","unity"and"exploita- tion",and follow a fair and just company style for management.Product production adopts five-axisand six-axis CNC grinding and machining centers from Germany,Switzerland,Japan,etc.,and is equipped with high-precision testing equipment such as Germany,Japan,and China,so as to meet the needs of production with high quality and quantity.

The company's team consists of 2 professor-level senior engineers in China,and has more than ten experienced tool technology and R&D personnel.It has formed a long-term cooperation model with East China University of Science and Technology,and continuously develops various high-performance CNC tools,and has won various national awards. Supply Wholesale NNX Carbide End Mills for Copper Electrode. More than 10 patents,the company's products are mainly used in the defense industry, aerospace industry,automotive industry,electronic products and molds and other fields.

The company's various products are recognized and favored by well-known domestic companies.With infinite technology,infinite creation,and pursuit of excellence,Magotan tools will write future prosperity and dreams with more extraordinary confidence and high-quality quality.

Does Changzhou Maiteng Tools Co., Ltd.'s NNX Carbide End Mills for Copper Electrode Perform Well When Processing Micro or Fine Feature Copper Electrodes?

Milling copper electrodes, especially those with intricate micro or fine features, is no trivial pursuit. The softness of copper, combined with its tendency to adhere to cutting tools, poses a persistent challenge to machinists. Precision, efficiency, and surface integrity must coexist in perfect harmony to achieve exemplary results. Enter Changzhou Maiteng Tools Co., Ltd., a beacon of engineering excellence nestled in the economically vibrant Yangtze River Delta region, and their NNX Carbide End Mills for Copper Electrode—designed specifically to conquer these hurdles.

Precision is paramount. Copper electrodes for micro or fine features demand machining tolerances of the highest caliber. Maiteng Tools delivers this with surgical exactitude. Their NNX Carbide End Mills for Copper Electrode are meticulously engineered to maintain ultra-high precision standards, ensuring that each contour and cavity is rendered flawlessly. Such precision is not accidental; it is the product of relentless innovation, sophisticated CNC grinding technology, and rigorous quality control, all hallmarks of Maiteng’s manufacturing philosophy.

Efficiency is another cornerstone. The unique blade geometry, coupled with an ultra-fine 0.2μm particle substrate, enables rapid, stable cutting that does not compromise accuracy. This advanced design facilitates high-speed machining, reducing cycle times without sacrificing surface finish or tool life. In an industry where time translates directly into cost, this efficiency is a decisive advantage.

Surface quality, often an overlooked metric, is crucial for copper electrodes destined for demanding applications in aerospace, defense, electronics, and automotive sectors. Traditional coated milling cutters frequently fall short, wearing quickly and leaving subpar finishes. Maiteng’s adoption of the latest Diamond-Like Carbon (DLC) coating technology transforms this narrative. DLC coating significantly extends tool longevity while producing surfaces of remarkable smoothness, elevating the end product to an entirely new echelon of quality.

The origins of such sophisticated tooling are rooted in Maiteng’s enviable location and ethos. Situated in Xixiashu High-tech Development Zone—China’s renowned tool manufacturing hub—the company benefits from seamless access to major transportation arteries including high-speed rail, expressways, and international airports. This connectivity ensures swift logistics and robust supply chain reliability.

Underlying the product’s excellence is Maiteng’s unwavering commitment to quality, certified under ISO9001 standards. The company’s production utilizes advanced five-axis and six-axis CNC centers sourced from Germany, Switzerland, and Japan, supplemented by high-precision inspection equipment that guarantees consistent adherence to stringent specifications. Their team, featuring two professor-level senior engineers and a cadre of seasoned R&D specialists, collaborates with East China University of Science and Technology to pioneer innovations that secure national patents and accolades.

Serving industries where failure is not an option, Maiteng’s NNX Carbide End Mills for Copper Electrode stand as a testament to the company’s core values of integrity, unity, and ingenuity. Their tools are not mere products but embodiments of infinite technological creativity and relentless pursuit of perfection.

In summation, when processing micro or fine feature copper electrodes, Changzhou Maiteng Tools Co., Ltd.'s NNX Carbide End Mills for Copper Electrode excel across every critical dimension—precision, speed, durability, and finish. Choosing these tools is a strategic investment in manufacturing excellence, ensuring that the complexities of copper electrode machining are met with confident, worry-free performance.